Noventum’s very own Brian Stinar is a woodworker. He enjoys creating, and repairing, things made from wood. Normally, this is a hardwood with a finish that brings out the natural wood grain, and some sort of sealant to protect it. Occasionally, it’s a cheap piece of pine which has a coat of paint on it.

He also used to be a programmer, before becoming a manager and salesman. He decided to combine woodworking and programming, by learning how to use the CNC router at a shared workspace called “Quelab.” His family has (had?) lazy Susan food trays, which are nice for putting hot food on a table, when 5+ people are sitting around the table and want some food. Like this:

Figure 1 – Top View

Figure 2 – Side View – Ignore the Chicken Food

Figure 3 – Screw hole access, while rotating, to assemble / disassembly the turntable

One of these split in half, since the wood was glued together without any sort of cross support. So the Stinar family added it to the Christmas fire, after removing the metal Lazy Susan turntable, and Brian decided to program a machine to cut an image of his family into this, instead of a generic nature scene.

Figure 4 – top view of rotating turntable

Figure 5 – side view of rotating turntable

So, he had to learn how to use the machine, by completing the 4+ hour Quelab training. This ended up taking closer to 8 hours, since instead of a generic, boring, example, Brian brought a vector file of both parts he needed (sans picture.) To make sure his measurements were correct, he also modeled this in 3D using OpenSCAD.

He cut the bottom piece, and realized centering the turntable in physical reality would be significantly more difficult than centering it in digital reality using design tools. So he modified his design, and added a 1/16th of an inch (sorry metric system) inset. This worked well:

Figure 6 – View of the initial bottom piece with jaggy support material left in place

Figure 7 – View of v2.0 of the bottom piece (2x) with insets for the turntable

The top piece will be similar, but significantly bigger. The bottom piece is seven inches (177.8mm) in diameter, while the top will be 17 inches (431.8mm.) The top will also have a thin, 1/4 inch lip, to prevent things from spilling, and to hold two part epoxy. The top part will also require a picture with the background removed.

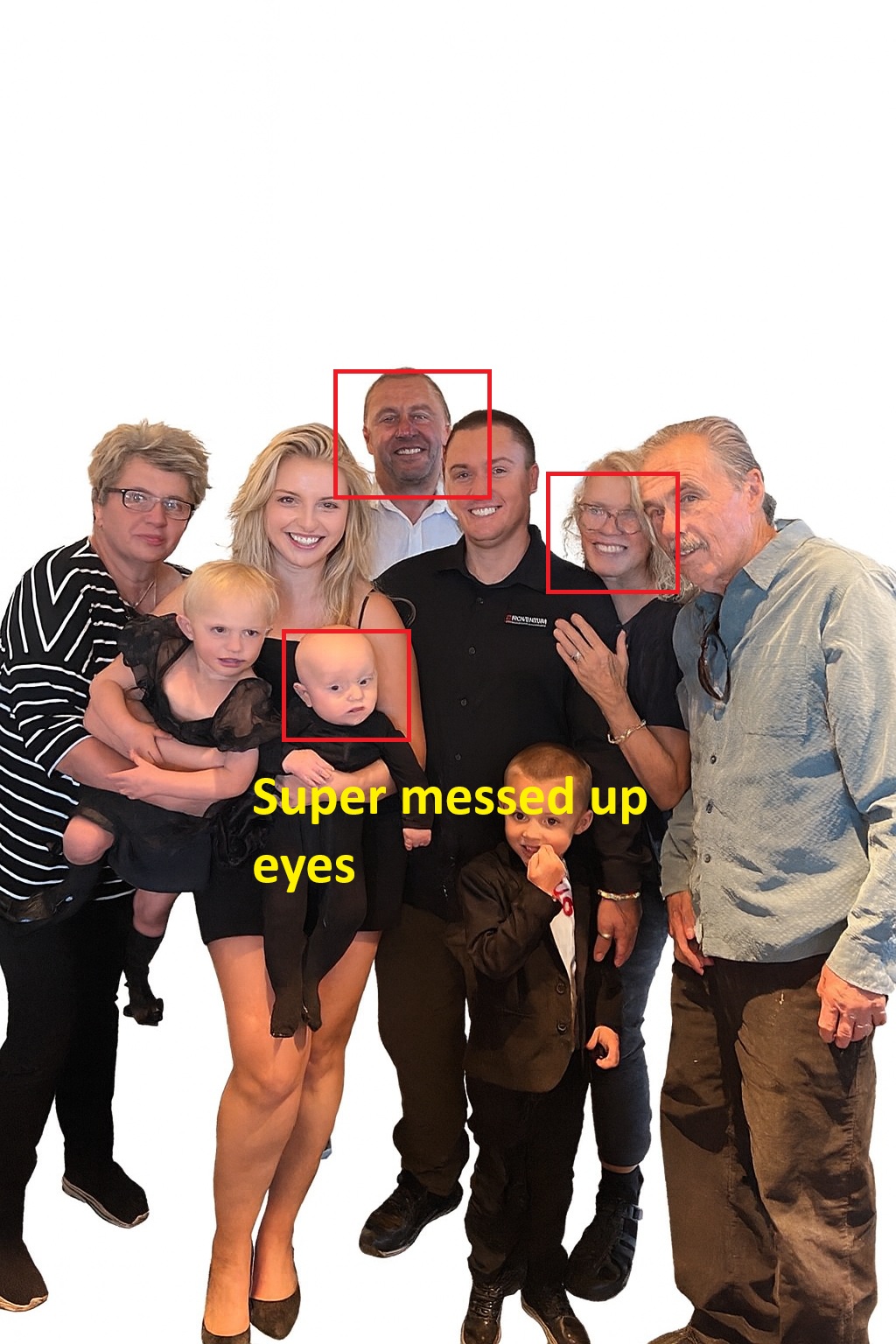

So, after understanding the industrial process in depth, it’s time to remove the background from the original image.

Figure 8 – Copilot generated raw image / with Brian’s annotations

Figure 9 – Chat GPT generated raw image / with Brian’s annotations

Figure 10 – Gemini generated raw image / with additional background removals by hand

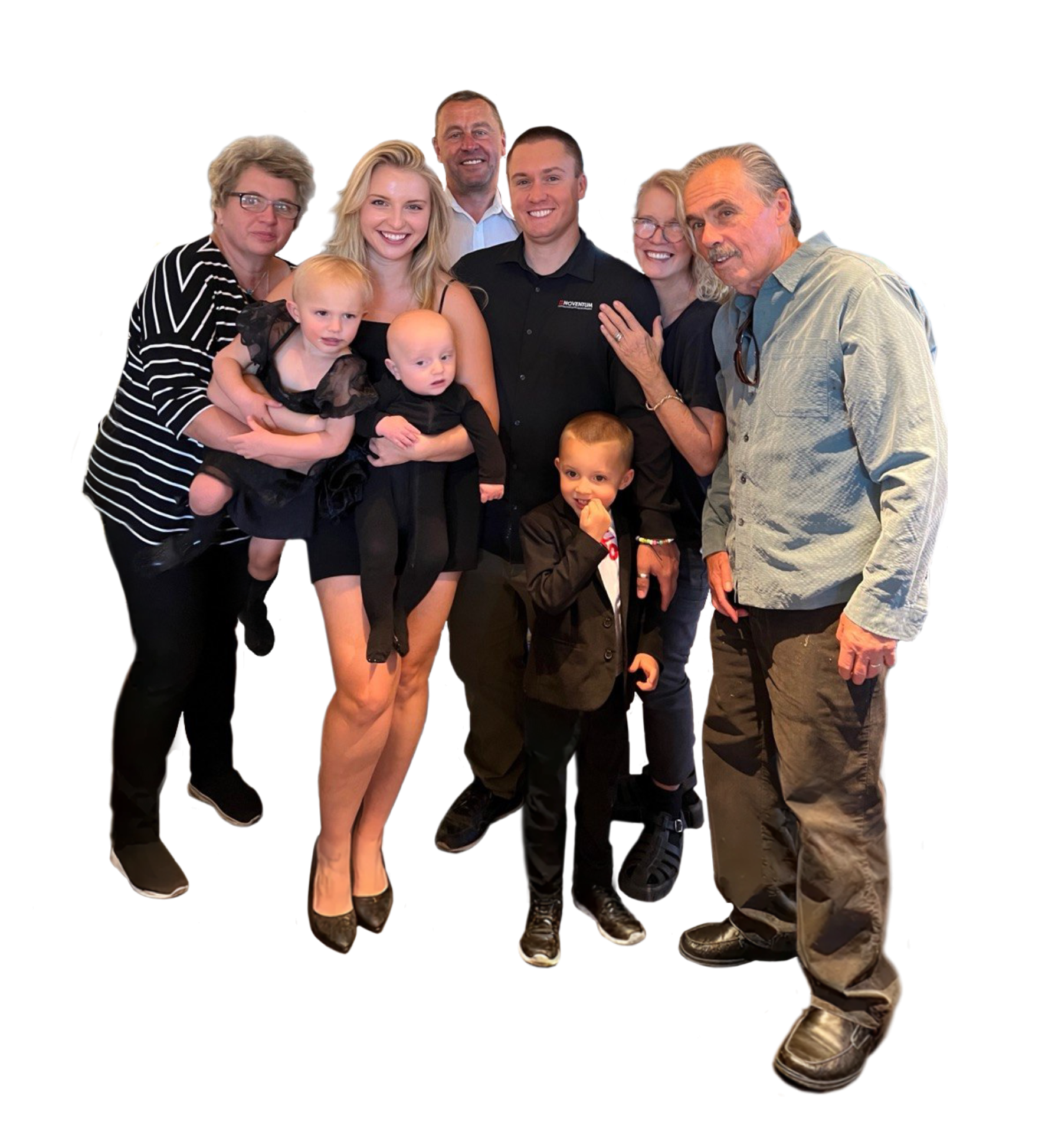

After all of this, Brian started talking with Daria about this project, and she decided to add legs to everyone using AI. These tools speed things up, but with Brian’s not-great photo editing skills, the time spent in messing around with the different AI tools was comparable to the time he would have spent removing the background by hand.

This isn’t finished. Brian still needs to cut the top piece, and etch an edited photo into it. This blog post will be updated as that happens.

Figure 11 – Initial Image

Figure 12 – Daria’s version: background removals by hand + AI generated legs

This experiment is a quiet reminder that AI is a tool rather than a replacement for human worker. It works well when tasks are simple and clearly defined, but as complexity and nuance increase, human insight becomes essential. For now, the most effective results come from a combination of AI capabilities and manual expertise.

Then, after cleaning up the image, Brian used the VCARVE software to turn this image into a series of toolpaths, to actually drive the router. He used settings from this YouTube tutorial, and a 60 degree bit to do so.

The first attempt was too deep…

… but attempt number two came out good, especially after adding some black spray paint:

Figure 13 – Error 1

Figure 14 – Good Outcome, No Finish

Here’s after finishing them:

Figure 15 – Everything Finished, whites for kids to paint

The final step was adding two part epoxy to the oak ones with etched photos. That came out well:

Figure 16 – Finished Products

Overall, this came out well. The 18 hours spend over Christmas Eve and Christmas Day wasn’t the best, but other than that, this was a success.

One of these split in half, since the wood was glued together without any sort of cross support. So the Stinar family added it to the Christmas fire, after removing the metal Lazy Susan turntable, and Brian decided to program a machine to cut an image of his family into this, instead of a generic nature scene.